Pre-treatments and Leaching of Rare Earth Elements (REE) from Malaysian Bauxite

DOI:

https://doi.org/10.51200/susten.v2i1.6174Abstract

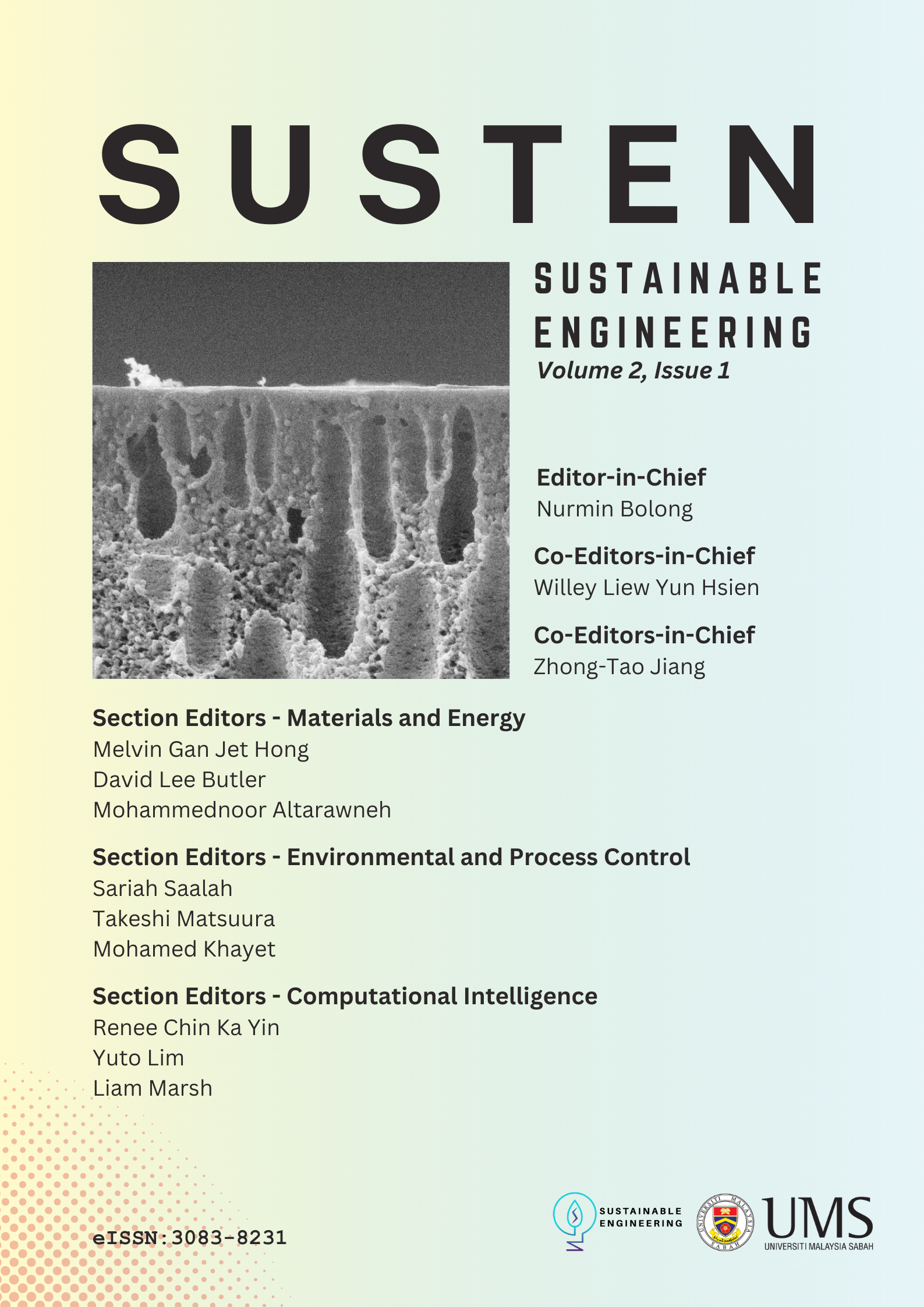

The importance of rare earth elements (REE) in high-end technology applications has become increasingly notable. Malaysia is rich in mineral resources like bauxite ore, which contains a significant amount of REE. However, REE from bauxite cannot be extracted directly without pre-treatments and the growing concerns of environmental pollution, such as red dust and red mud, are partially due to the increased stockpile of bauxite residue (BR). The study intends to compare the effect of pre-treatments before the REE leaching process of the RB from Felda Bukit Goh, Kuantan, Pahang. The methods 1 (M1) and 2 (M2) included roasting, magnetic separation, Bayer process, acid cracking, leaching via (NH4)2SO4, and precipitation via C2H2O4. In M2, lower current intensity in magnetic separation, a lower solid-to-liquid ratio and the absence of H2O2 in acid cracking were used. The RB contains light rare earth elements (LREE) between 190.20 to 318.71 mg/L with abundant cerium (Ce) and neodymium (Nd). The RB comprises of Fe2O3 44.66%, Al2O3 34.15%, TiO2 8.39% and SiO2 8.39% whereas gibbsite (Al(OH)3) was the main mineral. In M1, the REE contents decreased by 12.5% (301.31 mg/L) and between 0.4% to 8.4% after roasting and magnetic separation, respectively. Via the Bayer process, REE contents increased by 15.5% (346.81 mg/L) in M1, whereas decreased by 48.4% (119.34 mg/L) in M2. In acid cracking using H2SO4 with H2O2 in M1, the REE contents majorly remained in BR, while without H2O2 the REE contents decreased, indicating REE has been leached out in M2. The H2O2 caused the BR to become viscous and harder after drying, leading to the REE interlocking in the residue. The overall leaching performances in M1 and M2 were achieved at 1.34% and 99.0%, respectively, evidently showing that introducing H2O2 before the leaching process does not improve the REE extraction. Meanwhile, precipitation via C2H2O4, produced rare earth oxalate (REOx) up to 1.59 % in M1 and 31.80% in M2 where, based on element purity, the Ce and Nd in M2 attained were 92.78% and 7.20%, respectively.